Avalon Plus

Home Grading & Branding Avalon Plus

The "smoothness" of a facet is the degree in which polishing lines are visible. It is therefore an important aspect of the finish grade of a diamond’s facet. Because of the constantly increasing quality demands placed on polished diamond, smoothness becomes increasingly an important diamond quality feature .

The loupe

Many polishers evaluate ‘smoothness’ with a loupe (magnification 10x). The facet is observed under a small angle. The difficulty of this method lies in the positioning of the stone in relation to a light source, in order to put the facet in reflection (known as ‘scheerlicht’). Varying the light intensity by tilting the stone makes the polishing lines visible.

The microscope

The evaluation of ‘smoothness’ with a microscope is done in the same way as with the loupe, or through the stone. However, by using a microscope, one has better control of lighting conditions and stone manipulations. The availability of higher magnification is an additional improvement.

Avalon

By using a special light source, Avalon visualises the surface finish of a facet with very high contrast. This requires the facet to be positioned perpendicularly to the optical axis of the measuring tool, which can easily be achieved when the stone is still in the tang. This brings us to the essence of the device. ‘Smoothness’ can be observed by the polisher (during the polishing process and without having to remove the stone from the tang) and allows him to intervene immediately when necessary. The polisher will be able to visualise smoothness without any difficulty, whereas a later examination of the stone can only be completed with traditional and less user-friendly tools.

The result is an increased efficiency.

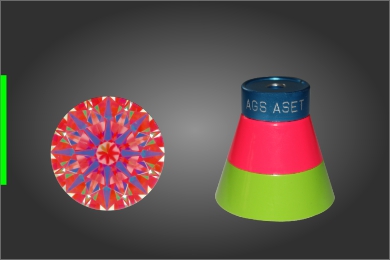

To minimise the polisher’s subjectivity when assessing a diamond’s smoothness, WTOCD developed an upgrade of the Avalon: the Avalon plus or Avalon+.

This upgrade allows facet’s smoothness to be objectively measured and colour graded according to the HRD Antwerp standards for polish grade.